Saturday, July 27th, 2024

Making Best Practice

Standard

In Your Business

Most managers think it's a good idea in theory to adopt ‘best practice’ throughout their organization. But in practice, most don't do it. It just sounds like a lot of hard work, having to write everything down, and then do everything ‘by the book’. It sounds like it will slow things up, and make the organization rule-bound and less creative.

Wrong. Quite wrong.

Adopting Best Operating Practices (BOPs) is actually easier, better, cheaper, faster, and safer. Not only that, it's cheap to do. You don't have to visit some university to find out what is best practice, or employ some expensive consultants to help you do it. For most companies, best practice is right inside the building! Let me give you an example.

A South African engineering company with whom we worked produces huge pumps for use in the oil and mining industries. These pumps are dependent on large rubber seals to make them leak-proof. However, figures showed that at least 15% of the product needed to be re-worked every month to patch up faults. While investigating the problem, the manager revealed that five of his operators produced flawless work month on month with no re-work requirements.

The five operators were requested to describe how they went about the job, and their method was captured and put on paper. The rubber department was then re-formed into five separate teams, each team having one of the ‘best practice’ operators acting as their team leader. That changed how the job was done throughout the section, and in a matter of three months the re-work they had wrestled with for so long had fallen by some 80%.

That is the prize of capturing and using the best operating practices right inside your own business. Not only does the company gain a benefit, employees feel proud to have contributed. The greatest compliment you can pay your own employees is simply to listen.

Writing up BOPs is a good idea for any company to take up. Here's why.

BOPs Deliver Better Quality

BOPs describe any process in a step by step way, so that anyone with the right materials, equipment and training will turn out a good product or service every time. That's its key purpose. Writing BOPs press you into making sure you put all the elements in place to achieve the consistent quality you as a manager would want to see. You start to ask questions like :

- Have we got the right materials to produce a quality job?

- Is the equipment we are using capable of delivering a quality job consistently?

- Are the tools good enough?

- Have we got the right information and systems to deliver good quality?

- Have my people all had the right training?

- What do I need to do now to make that happen?

The act of writing down the process also urges the manager to find out who already does the job best, to capture that, and make it available to all their staff. Just spreading that knowledge will immediately produce more consistent and reliable quality. It's a process many Japanese companies started long ago, until now the quality and reliability of their products have become quite legendary.

One of the first companies to do this was car company Toyota. Taiichi Ohno, for many years their Operations Director, and acknowledged originator of their ‘zero defect’ policy, was a great believer in BOPs. The company described the detail of all their jobs in what they called Standard Work Sheets, their in-house version of Best Operating Practice. Here's what he said about them.

“Standard work sheets and the information contained in them are important elements of the Toyota production system. . . . We have eliminated waste by examining available resources, re-arranging machines, improving machining processes, installing autonomous systems, improving tools, analyzing transportation methods, and optimizing the amount of materials at hand for machining. High production efficiency has also been maintained by preventing the recurrence of defective products, operational mistakes, and accidents, and by incorporating workers’ ideas. All of this is possible because of the inconspicuous Standard Work Sheet, which has changed little since I was first asked to prepare one 40 years ago . . .”

BOPs Are Good For Productivity

One of the benefits of writing down all the steps in a BOP is that you start to ask other pertinent questions. Like :“Do we really need to do all this?” Or, “Why do we do that?” [The usual answer is : “We've always done that”.] Then you start to get intolerant of any steps that don't add value.

In this context, a value-adding step is : ‘anything that changes the product or information in some way, so that it is of value to the customer’. By ‘customer’, we mean whoever gets the result of your work; and that person can be inside or outside the business.

To take an example. A nurse takes information from a patient, composes it into a form which can then be used by the doctor to help diagnose or cure the patient's ailment. That's a value-adding step. A production operator in a car factory takes a piece of raw metal and machines it into a gear, which can then be used in a car's gearbox. That's adding value. A Finance Manager takes raw data from Sales, Buying, Production and other departments, and composes it into Accounts, which can then be used by managers all round the business. That's adding value.

BOPs are an opportunity to eliminate all those steps which don't add any value. For example, it may be that information provided by one department on one kind of form then has to be re-entered on another form in the next department. That's adding cost, but no extra value. The rule there is : enter data only once in a format that can be used by everyone. Another example : a product made by a competent employee has to be examined by an inspector before it is allowed to go on its way. The ‘inspection’ step adds cost but no extra value (product not changed in any way), so eliminate it. If the employee is competent to make the product, they are also competent enough to check its quality in the process.

In our experience, we find in manufacturing companies that on average 25% of process steps add no value at all. Surprisingly, in office environments we find that average figure to be even greater, at around 40%. That's why BOPs are great for productivity - there is so much to go for by seeking out and eliminating those non-adding-value activities. The greatest improvements in productivity don't come from employees ‘working harder’, that's usually small beer. Changing the process is where the biggest improvements lie.

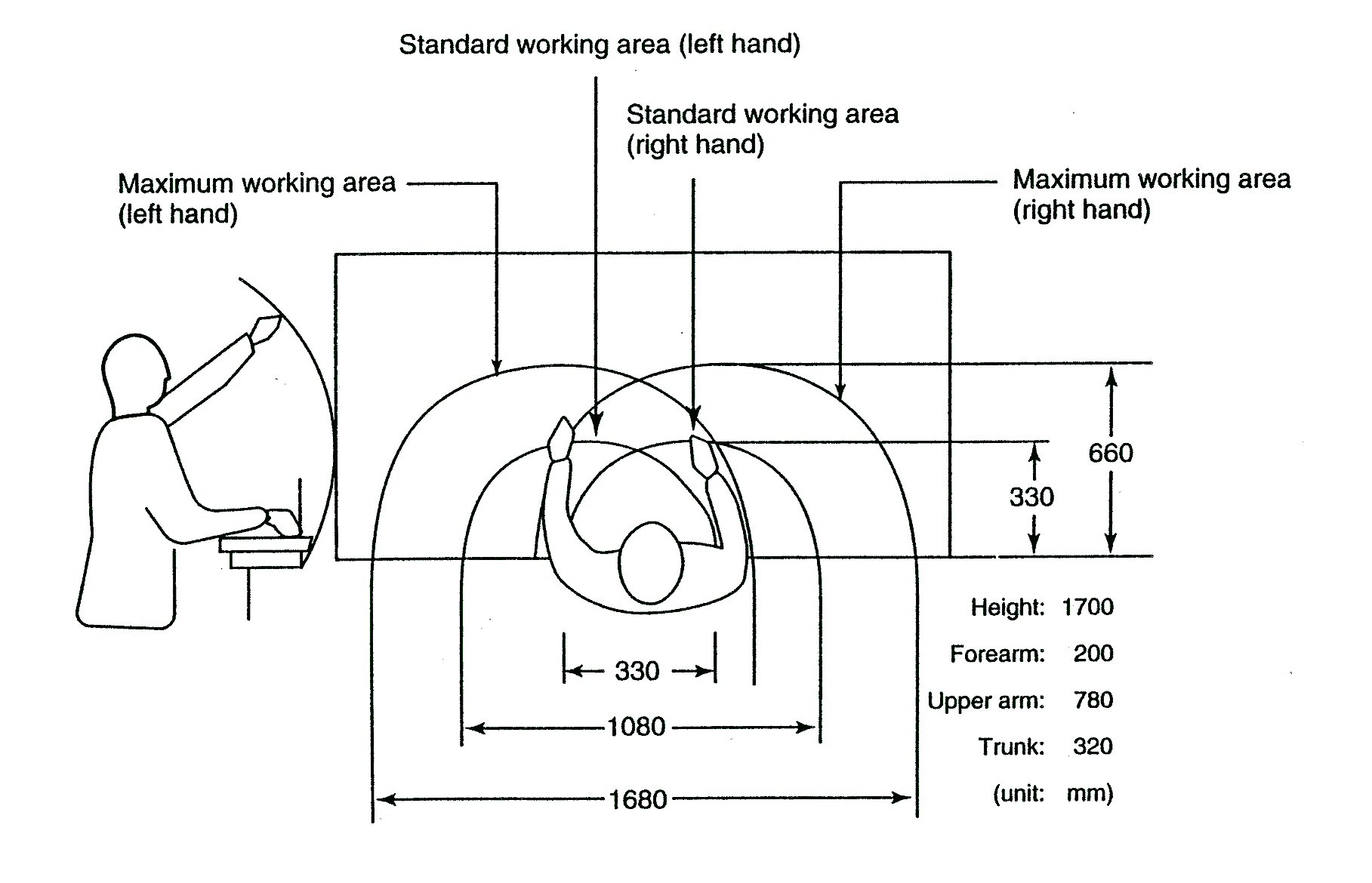

One of the most productive approaches to that is to concentrate on making the job easier to do. As a rule, we know that will add at least 10% more productivity by itself. For example, if employees are using the same items and equipment repeatedly in doing their job, then it's useful to keep these regular items within easy reach, so that they can get into a rhythm and don't have to stretch or strain. Here's a drawing which will illustrate the point.

In a small parts assembly situation, it is obviously helpful to have all the items used repeatedly as close to hand as possible. Those used less often can be placed at a stretch (an extended arm), but still within reach. The same applies to an office desk job - all the paper, pens, pencils, staplers, calculators etc. need to be easy to put your hand on. Twisting, getting into awkward positions, having to walk back and forward to files, etc. should be out.

BOPs Are Good For Cost-Saving

One of the intentions behind BOPs is to devise a method of doing the job right first time. That's because not doing the job right first time adds to your cost but produces no new value for your customer. The customer gives you no more money because you had to work overtime to re-do the job, or had to scrap items not made right, they don't care about that. That cost is all down to you.

And often, that cost is hidden. Let me give you an example. A while ago, we ordered some telephone headsets for our business, which had a telephone earpiece on one side only (so we could hear other people in our office). When they arrived, they were all double-sided. We phoned the company : "Send them back," they said. We did. The second set they sent were exactly the same, double-sided. We phoned again, we sent them back again. We finally noticed that the labels on the headset boxes all said 'single-sided', but someone had put double-sided headsets into single-sided boxes!

All this to-ing and fro-ing, searching out the products, sending them out, getting them back, re-sending them out several times over, not only adds to the company's costs, it irritates the customer as well. So it's actually costing the company more to ruin its own reputation. It's a 'lose-lose' situation however you look at it. A key function of the BOP is not only to avoid all that embarrassment, it's to save the needless hassle and cost of putting things right that should have been right in the first place.

BOPs Are Good For New Employees

When new employees join any company, someone is generally assigned to show them how to do the job. If the current employees are already working to the BOP for the job, that is what they will teach the new employee. Not only that, they will insist the new employee reads the BOP, to make sure they understand what is required, what points to pay particular attention to, problems to avoid, etc. That way, they won't be picking up any bad habits by default; on the contrary, they will be learning and doing the job the best way the company knows how - from the beginning.

McDonalds, the hamburger chain, is a great example of this philosophy. Whether or not their products are to your taste, they get an awful lot of customers passing through their doors all round the world : 50 million every day in 119 different countries. They are very committed to their core QSC principles : Quality, Service and Cleanliness. But there is no way they are going to deliver that consistently to their customers, with 31,000 restaurants and a million and a half employees, unless they are pretty specific about how to do it.

When the McDonald Brothers started they had 15 ‘Do's and Don'ts’ they wanted their people to observe. That soon developed to a 75-page bound manual; today that manual extends to more than 600 pages. Every operation is described specifically : the famous French fries must be 9 / 32 of an inch thick, they must be cooked in the right oil for a specific number of minutes; if they are not purchased within ten minutes of cooking, they must be discarded. It's quite clear, no questions needed, that's the way we do it, it's the best way we have discovered of delivering to the customer the quality product they expect.

That's great for new employees. The Best Operating Practices described in ‘The Book’ make it clear just what they have to do. They know they are expected to greet every customer with direct eye contact and a smile. They know how quickly customers should be served. They know what to say, they know what to ask, and how to do it. When cooking hamburgers, they know how to lay them out on the griddle, what temperature to cook them at, for how long, how to turn them (not flip), to get the right finished product.

Many of the company's staff may be only sixteen or seventeen-year-olds, or on their first job, but they all follow the BOP routine. That's why McDonalds achieves the same standards of quality, service and cleanliness wherever you are in the world. It's why customers and families go there in such numbers, because they know what they are going to get. BOPs have made McDonalds into one of the most successful restaurant chains anywhere in the world.

BOPs Are Good For Continuous Improvement

Once the BOP has been written for any job, it's not a static thing. There are always ideas that occur to managers and employees which could make the job easier, better, cheaper, faster or safer. When they prove that the new idea really works, they build it into the BOP. It's like the Olympics - things never stop improving.

Decades ago, Japanese companies realized they were never going to compete in world markets without improving their product quality. That's when they adopted their kaizen philosophy. The word actually means ‘good change’, but in the West has come to mean ‘continuous improvement’. Japanese managers take continuous improvement to be a key part of their job. In fact, Masaaki Imai, who wrote the book ‘Kaizen’, says when he was first appointed as a supervisor, his boss told him : “If the job is being done exactly the same way in six months' time, see that as a failure”. He got the message.

The great advantage of writing Best Operating Practices is that you capture what is best in what you do now. Thereafter, the tweaks and improvement ideas you come up with enable you to go even further, but importantly you don't lose what was good in the first place. Step by step, you get to places you never thought you would achieve. Every time I quote the next example by way of illustrating the point, I still find it quite mind-boggling, but it's absolutely true.

Back in the eighties, Motorola, the electronic devices manufacturer, were getting customer complaints about their product quality, so they decided to attack the issue with some vigour. When they started, their defect rate (only ½%), was already good by industry standards (in other words they were getting 995 items out of 1,000 right first time). So they began measuring defects by ‘parts wrong per 100,000’ to keep pushing ahead. Seven years later, the company ran full-page advertisements in Sunday newspapers to tell the world their product quality had improved a hundred-fold since they started.

But the quality standards continued to rise, with the company's Six Sigma programme eventually setting a standard of no more than 3.4 defects per million - an incredible 1,200 hundred times better than their start-point! Now you may think it would take any company years to get there, and in the first instance for Motorola, it did. But when the company opened a new plant in China, it found it was achieving the same Six Sigma standard in six months with completely new employees. That's the hidden power of BOPs - they take you to levels of performance you have never reached before.

BOPs Are Good For Safety

One important element of a BOP is to describe the safe way of doing things, that is : safe for the employee, and safe for the customer. In this respect, the rule to follow is not to make the job ‘as safe as possible’, to the extent that it kills productivity, or makes the job tedious and boring; but to make the process ‘as safe as necessary’ to do both a safe and effective job.

Most often, the safety parts of a BOP are ‘things to check’ before starting the job, or to watch while doing the job. That process is very familiar to airline pilots. They all systematically go through their checklist before they ever take off : are all the instruments working? the lights? the wing flaps? the tail rudder? the radio? the windscreen washers? etc. etc. And they need to. It could be a life-or-death matter. On a twelve-hour journey to Tokyo or wherever, the pilot can't just pop out of his cabin to ask the passengers if there's an engineer on board. They've got to get it right before they start. It's a necessity airline engineers are only too aware of. But these simple BOP checklists are one of the key reasons that airline transport is one of the safest forms of travel in the world.

The simplest form of BOP is just a checklist, but it can have far-reaching consequences. Recently, a group of heart surgeons decided to produce a checklist of questions that doctors could use to make good diagnoses of patient problems. Not everybody can be a specialist, but this was a way of imparting specialist knowledge to local practitioners to detect problems early, and thus improve the chances of survival for many patients. With local GPs using the checklist systematically, the heart surgeons were surprised how well the system worked : it was like they had been there themselves. What surprised them even more, given their long experience, was how lackadaisical they had become when they themselves didn't use the checklist. Some even said the doctors had become better than they were. That's the benefit of writing, and using, BOPs : it both spreads good practice around, and prevents experienced people getting slipshod too.

What The BOP Should Include

- A description of the job to be done.

- The material, equipment and tools involved.

- The method to be used, including particular key points to be watched.

- A description of what a good job looks like.

- The measurement methods to be used, so that the job holder will know when a good job has been done.

- The most common faults, and how to correct variances.

- The name of the person who wrote the BOP, and the date when it was last updated.

Here it is good to use diagrams or pictures whenever possible. We prefer to have a finished product in model form on the wall close to the job location, and, where required, an exploded version of the parts that make up the job, where each part has its own specific name. In an office situation we like to have ‘model’ completed forms to guide those who are using or completing them. In some cases, a video is even better.

Primarily, BOPs are designed to achieve the following:

- A description of ‘the best way we know how’ of performing a particular task

- Ensuring no-fail quality is built into the process

- Removal of ‘waste’ from the process

- Providing a safety-assured method

- Encouraging continuous improvement

How BOPs Are Used

Generally employees will consult the BOP when they are new to the job, when they haven't done that particular job for some time, or when they want to check a point which may have begun to slip over time. Pictures, drawings and illustrations are most desirable, but real model examples close to the work are best. One UK manufacturer of baths and basins has to deal with a great variety of water-managing systems, plungers and cisterns. In the cistern manufacturing section, some thirty varieties of the mechanics are mounted on boards and hung on the walls. Each time an operator has a batch to produce, he takes the appropriate board from the wall, places it in front of himself on the work-bench, and starts to work with the model product and parts right in front of him. That's good BOP practice.

BOPs don't have to be rigid or elaborate. They just have to encourage best practice. In laboratory situations, it would be the step-by-step safe sequence for executing processes. In a hospital, it is even more important to do the work ‘the best way we know how.’ One geriatric hospital group encourages their staff to write up their processes as a standard for the whole group this way : when the process has been examined and approved, it is entered in ‘The Beautiful Book’. Their employees love to have their name recorded in The Beautiful Book.

In office-based situations, forms can play a big part in communicating and storing key information. Yet it is pretty commonplace for people to complete forms inadequately. Sales people will often omit important information from their sales order forms, or job applicants will struggle filling recruitment forms when they are not quite sure what is required. That's where BOPs may take the form of a manual of ideally-completed forms. Seeing what a properly completed form looks like is much better than simply being given a blank form to complete.

BOPs Are A Key Managerial Job

Often when we are addressing groups of managers or employees, we will ask the question : “How many of you think we shouldn't do things in the company the best way we know how?” No-one ever puts their hand up. They all think we should do things the best way we know how. That's why it is so important for the manager to set out in detail best operating practice for every job in his or her department. It can take time to do all that, of course, but I would say : there is no job more important.

Employees are not going to fall into ‘best practice’ by accident. The why's, the wherefores, and the detail have to be demonstrated and explained. But because the vast majority of employees actually prefer to do a good job, when you describe the BOP, and you give them the materials, tools and training to do that good job, that is just what they will do. The BOP is what makes best practice into standard practice in your company.

When composing BOPs it's vital to involve the people doing the job. You'll have ideas, but they will too, and it's important to build the best ideas into the BOP, wherever they come from. Furthermore, employees are flattered that you have consulted them, and shown such respect for their opinions. Also, the ownership they feel in the process makes them much more committed to following the BOP when it's finished. It's a win-win situation for the manager.

A final point. Although it's important to be open and democratic when composing the BOP, the manager needs to be relatively autocratic in implementing it : ‘It is not optional to follow best practice when we know what that is; that's what we do : we follow the BOP. If someone comes up with a new and better idea, we will build it into the BOP to make sure we don't lose it. But until then . . . we follow the BOP’. Eventually, it will become a habit to do just that. That's when ‘best practice’ will have become part of the company's culture, part of ‘how we do things round here’.

* * * * * *

If you would like a PDF version of this article to print or copy click here.

On the other hand, if you have any questions you want to ask on the subject, click here to send us a quick email, and we'll try to respond as soon as we can.